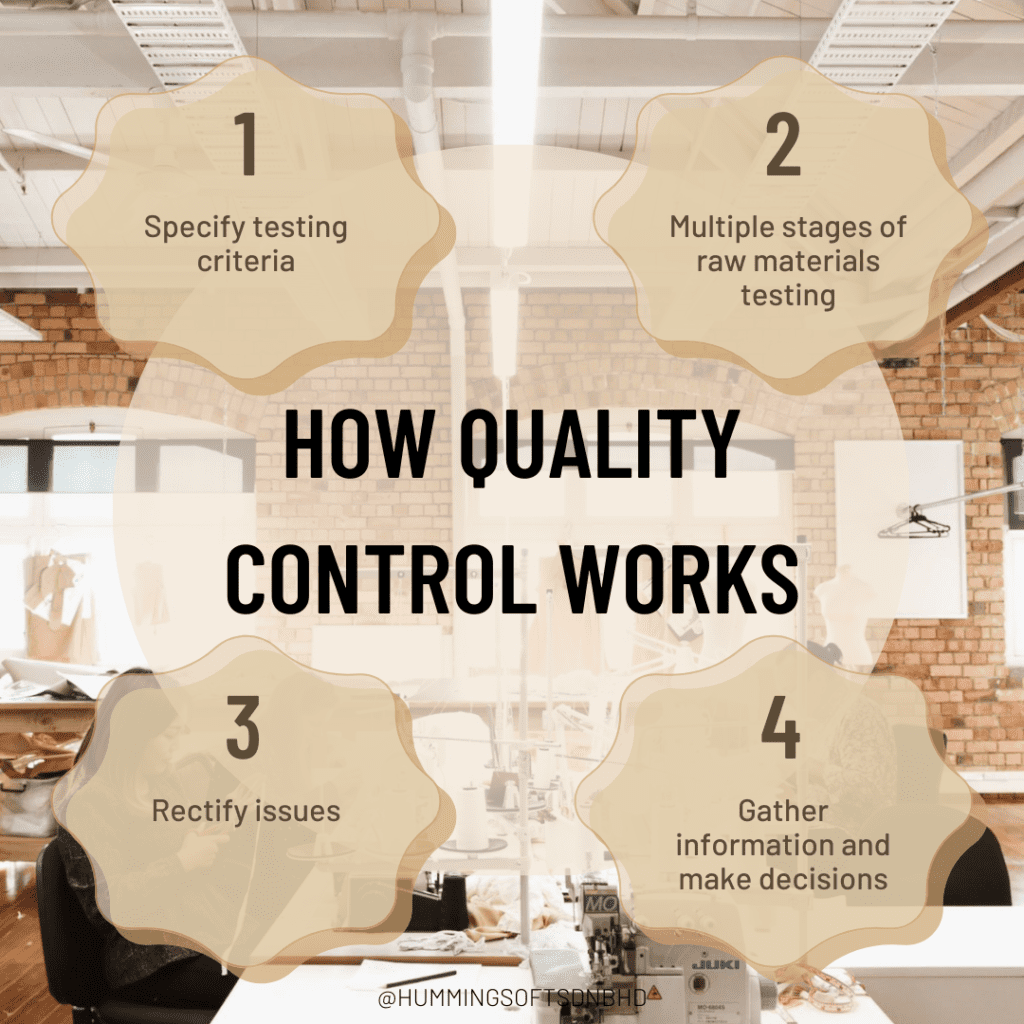

1. Specify testing criteria

A business must first choose the criteria it intends to satisfy before putting in place a quality control programme. It then decides how far to go with the actions. For instance, the group must choose how many samples to collect and analyse.

2. Multiple stages of raw materials testing

The majority of the time, quality control involves checking each stage of a company’s production process. For instance, QC staff members can start by testing the raw components that go into making a product. To locate any flaws, they could carry out additional testing at different points in the manufacturing process.

3. Rectify issues

To stop them from happening again in the future, employees fix the issues present. Depending on the product and industry, a corporation will utilise a certain form of quality control. For instance, in the production of food, the company’s quality control team does microbiological testing to make sure the finished product won’t make consumers ill and may examine the food in its packaging to make sure it’s aesthetically pleasing. However, quality control in the auto sector may concentrate on how various components work and interact with one another.

4. Gather information and make decisions

Employees then, gather information from the actual world and provide reports for the management to analyse and decide whether any further measures need to be taken. For instance, the business might want to get rid of or fix any lingering defective machines. Similarly to this, if too many items are faulty, it is better for the business to develop a plan for streamlining the manufacturing procedure or, if the issue is with the supplies being utilised, buy raw materials from somewhere else. The business must keep using its quality control procedure to keep an eye out for any fresh indications of issues.